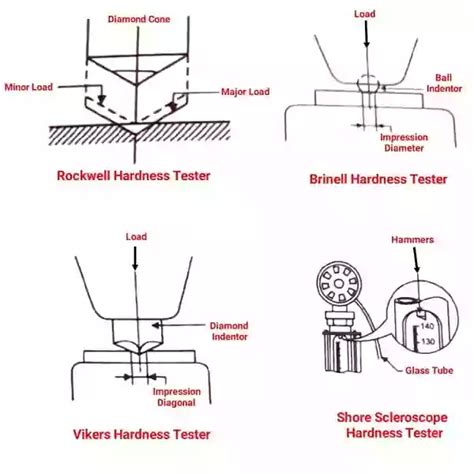

edges of material hardness test|hardness tester information : OEM The type of material and expected hardness will determine test method. Materials such as hardened bearing steels have small grain size and can be measured using the Rockwell scale due to the use of diamond indenters and high PSI loading.

AUD-20200224-WA0003 LRC Lyrics - Donwload, Copy or Adapt easily to your Music LRC contents are synchronized by Megalobiz Users via our LRC Generator and controlled by Megalobiz Staff. You may find multiple LRC for the same music and some LRC may not be formatted properly.

{plog:ftitle_list}

2014 - Outlander Season 7 - All subtitles for this TV Series . Find the right subtitles. . S07E05 Singapore. 34 Latest: 5 months. Download. n/a% 0. S07E06 Where the Waters Meet. 41 Latest: 4 months. Download. n/a% 0. S07E07 A Practical Guide for Time-Travelers. 46 Latest: 5 months.

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .The relevant standards for each of the different test methods specify minimum distances between the test points (indentations) as well as to the specimen edge.The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 years.

When making indentations on a test block, the hardness of the material immediately surrounding an indentation will usually increase due to the residual stress and work hardening caused by the indentation process. If an indentation is made too close to the edge of a test piece, there may be insufficient material to constrain the deformation around

The type of material and expected hardness will determine test method. Materials such as hardened bearing steels have small grain size and can be measured using the Rockwell scale due to the use of diamond indenters and high PSI loading.Case depth testing often involves performing a series of hardness impressions from the edge of the specimen towards the center. The hardness progression is plotted on a graph and the distance from the surface to the hardness limit (HL) is calculated.

To prevent the material from being pushed over the edge of the specimen during testing and therefore pretending a lower hardness value, the center of the indentation should be at least as far from the edge as 2.5 times .research a suggested procedure for hardness testing of ther mal cut edges of steels where testing variability is minimized. MATERIALS The original AISI project evaluated the thermal cutting per formance of A572-Grade 50, A588 and A36 steels. The pro duction size plates were in thicknesses of 1 in., 2 in. and Element C Mn P 8 Si Ni Cr Cu . Hardness testing is widely used in a multitude of industries and plays particular significance in structural, aerospace, automotive, quality control, failure analysis, and many other forms of manufacturing. . During specimen testing or coupon block verification, the spacing between indents, as well as from the material edge, must be properly . The Vickers hardness test is a versatile method to measure material hardness in practice. In this study, a comparison of cut-edge hardness between the thermal and mechanical cutting processes was performed on the structural steels S355 and S1100 by using the Vickers hardness test method with a small angle at cut edges to widen the heat-affected .

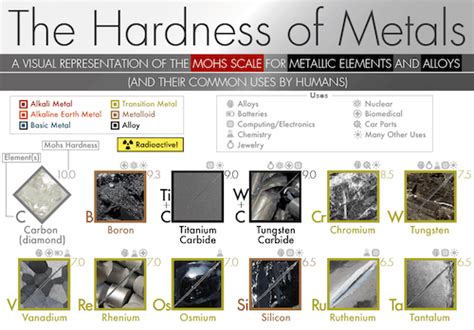

types of material hardness

Vickers Hardness Test. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or . Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in. . the distance from the center of any indentation to the edge of the test piece shall be at least two and one-half times the diameter of the indentation. The purpose for these distances is .The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness.

Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .The relevant standards for each of the different test methods specify minimum distances between the test points (indentations) as well as to the specimen edge. The reason for these minimum distances is to avoid distortion of the hardness testing results, which could result from the deformation of the material structure.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .Vickers Hardness Test. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or .

The Brinell hardness test – For this hardness test the measurement of the depth of indentation caused by the preload gives the hardness value of the material. However, the load range is between 5 – 250kgf often applied for testing the hardness of plastics using a tungsten carbide ball of between 1 – 5mm diameter.

For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .

Therefore, in cases where Rockwell hardness testing is to be made on narrow width material or material having a small area size, a Rockwell scale must be chosen that produces indentations small enough to prevent this edge interaction. 3.1.4 Test Material Homogeneity The size and location of metallurgical features in the test material should be . It is often used to determine the success or failure of a particular heat treatment operation or to accept or reject material. Hardness testing is thought to be one of the easiest tests to perform on the shop floor (Figure 1) or in the metallurgical laboratory (Figure 2) but it can be one of the hardest tests to do properly. . Readings taken .

vertical impact test

The procedure of hardness testing in engineering materials involves step-by-step instruction including selection of an appropriate scale, preparation of the sample, application of preload and major load, and measurement. . including interactive flashcards, comprehensive textbook solutions, and detailed explanations. The cutting-edge .More simply put, when using a fixed force (load) and a given indenter, the smaller the indentation, the harder the material. Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness Testing Considerations The following sample characteristics should be . Hardness testing ensures the materials utilized in components we use every day contribute to a well engineered, efficient and safe world. . is made too close to the edge of a test piece, there may be insufficient material to constrain the deformation around the indentation. Both of these scenarios can lead to inaccurate hardness readings.

vertical impact tester

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals .The hardness of a material is a measure of its resistance to localized deformation, scratching, or indentation. . Why is it important to know the hardness? Hardness testing plays an important role in materials testing, quality control and acceptance of components. as it directly affects the performance, durability, and reliability of these . (4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity must be met to obtain the same HB value, that is, the opening angleφ of the indentation is equal.. Method: The same HB shall be measured for samples with .

The hardness test is a depth difference method that measures the resistance of the material to permanent deformation. For this purpose, a penetrator is pressed onto the material with a specific test force. The resulting penetration depth or the permanent impression in the test specimen is then measured, and the hardness value of the metal is calculated. Consumables for the Vickers Hardness Testing System. The simplicity of the Vickers hardness tester allow for a relatively narrow choice of consumables and applicable spare parts. They include: The Indenter. A unique feature in the Vickers hardness test is the fact that every procedure always uses the same indenter.that contains movable knife-edges. The Vickers hardness values are calculated by the formula: ( ) ( ) 2 2 2 sin 2 1.8544 P HV P d d . HARDNESS TESTING IN ESTIMATING OTHER MATERIAL PROPERTIES: Hardness testing has always appeared attractive as a means of estimating otherWhen you require precise measurements for materials with high hardness or thin coatings – the Vickers hardness test is suitable. When needing to perform hardness testing on-site or non-destructively – the Leeb hardness test provides portability and convenience.

The Brinell scale characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science.Hardness Testing Basics Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 years. As a material property, its value and importance cannot be understated; the information from a hardness test can be used to .

types of hardness testing methods

The system offers cutting edge features above and beyond the standard HPEII model. The system is capable of taking a hardness value while a temperature sensor mounted on the bottom of the device is taking a temperature value. . This allowed for the calculation of the Brinell Hardness Number, which provides a quantitative measure of material .

types of hardness tester

Resultado da 681.7K. 1M. Raluca (@raluca_granolawn) no TikTok |80M curtidas.3.1M seguidores.Assista ao último vídeo de Raluca (@raluca_granolawn).

edges of material hardness test|hardness tester information